Feed Force Measurement

Simply know what nobody sees

Advantage through technology!

In addition to the drilling resistance, it is the second measured variable of the IML-RESI PowerDrill® and provides additional information about the condition of the interior of the wood. This is because while friction on the drilling needle shaft (shaft friction) can have a strong influence on the drilling resistance, it has only a minimal influence on the feed force. As a result, the feed force together with the drilling resistance allows very realistic conclusions to be drawn for assessing the wood.

Display of the feed force as an additional measurement curve

The IML analysis software displays the feed curve together with the drilling resistance curve in a graph. Both curves are color-coded. For a precise evaluation of the measurement results, it is important to interpret both curves in relation to each other and not just one measurement curve in itself.

Häufige Fragen zu „Feed Force Measurement“

Applications for feed force measurement

IML Wood testing systems for

feed force measurement

-

IML-RESI PowerDrill ®

IML-RESI PowerDrill ®The IML PowerDrill® is equipped with an electronic unit that gives clear support in taking, documenting and evaluating measurements. It can be used wherever reliable and meaningful measurements are required.

5.675,00 €

We have been cooperating very successfully and quality oriented with IML GmBh for several years. Problems?! There are none, because the team of IML is very friendly and helpful when ordering and in any technical direction to their products. They are up to the smallest detail. Definitely on a level 10 in a rating of 1-10. Thank you very much for the many years of good cooperation.

I previously worked with the IML-RESI B400 for years. This device worked flawlessly, due to the year of manufacture it had a rather Russian design. I am glad to have owned the B400 – so I can enjoy the advantages of years of development for the new PD-400: faster, much lighter, more compact, almost self-explanatory menu and eternally lasting battery! You can tell there’s a lot of attention to pragmatic detail here!

The many years of trustful cooperation in the segment of wood testing systems is of great importance on the part of FA. IML GmbH is characterized by high product quality and product development. In addition, the technical support is traget-oriented (very important for us), which is optimally implemented by the systematic approach of the respective employees. Questions, suggestions and if occurring ‘problems’, are immediately provided with a solution. In short, we feel that we are in “the best of hands”. Many thanks!

Articles about feed force measurement

IML-RESI PowerDrill® Under Water Device

Drill resistance- and feed force measurement for timber under water A reliable and efficient method for timber inspection The IML-RESI PowerDrill® provides meaningful measurement results that enable you to reliably evaluate the…

Wood inspection confirms suitability of wood as building material in avalanche protection

Student of the University of Applied Sciences Munich uses IML-RESI PowerDrill® with more than 450 measurements in his final thesis In the context of traffic safety, various wooden structures are used in…

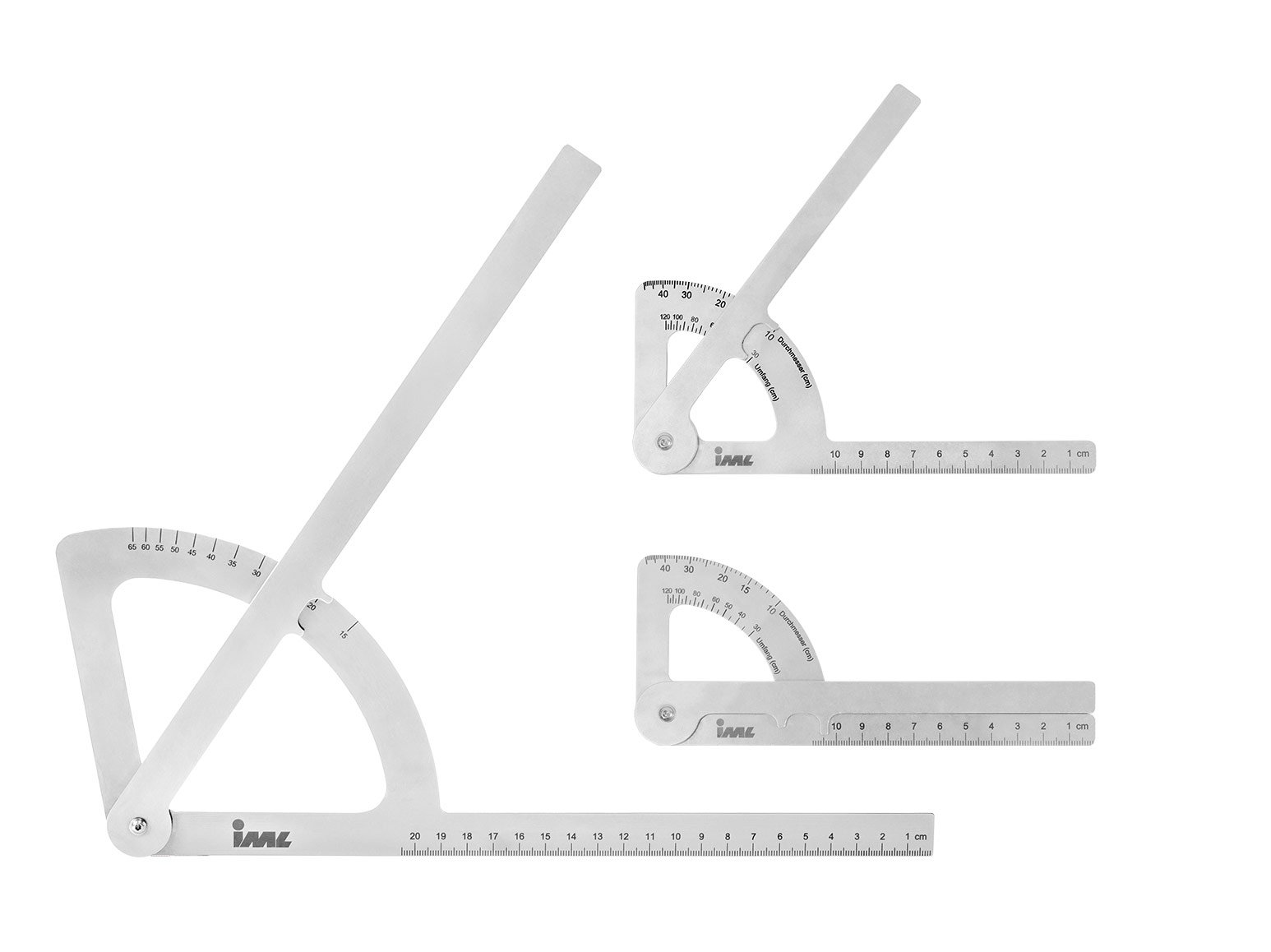

Tiny helping tools for timber pole and tree inspection: the new IML measuring gauge

IML (Instrumenta Mechanik Labor) has developed a measuring gauge with which you can measure four parameters at once.

Restoration of the Vineum in Meersburg – How Holzbau Schmäh impresses with the IML PowerDrill®

Restoration of the Vineum in Meersburg – How Holzbau Schmäh impresses with the IML PowerDrill®

Feed force measurement – Simply know what nobody sees – Advantage through technology

High accuracy for hard wood and early wood decay The feed force is the force required by the drilling needle to penetrate the wood. Besides the drilling resistance it is the second…

Engineering office Nieke about the IML PowerDrill® for the inspection of timber constructions and timber buildings

Since 2014 we have been using the IML-RESI PowerDrill® to measure drilling resistance in order to assess the condition and safety of wooden buildings and wooden constructions in houses. This enables us…

Annual Ring Analysis

Identifying the growth characteristics of trees Annual Ring Analysis The growth behavior of trees provides important information about climatic circumstances and temporary or persistent changes of the environmental conditions. In order to…

Bending and Compression Strength Measurement

Evaluating objectively the strength of wood Bending and compression strength measurement Just to make sure: With the Fractometer it is possible to determine the parameters of bending fracture strength and (depending…

Sound Velocity Measurement

Modern technology, easy handling Sound Velocity Measurement The IML Micro Hammer measures the time it takes an impulse to travel through the tree. Due to the characteristic sound velocity of each tree…