Student of the University of Applied Sciences Munich uses IML-RESI PowerDrill® with more than 450 measurements in his final thesis

In the context of traffic safety, various wooden structures are used in the mountains as avalanche protection. One example of this is the so-called wooden snow rakes, which are intended to prevent avalanches from breaking of. It is intended that the wooden snow sheds will perform this task for 30 to 40 years, while natural protection is provided by the forest. In his master’s thesis at the University of Applied Sciences in Munich, Benjamin Müller used an IML-RESI PowerDrill®, among other things, to investigate the condition of the wooden snow shears at Grüneck near Wildbad Kreuth, which are on average 25 years old.

Various avalanche protection measures increase traffic safety

Climate change and the intensive use of certain mountain areas increase the risk of natural hazards such as avalanches. In order to ensure the highest possible level of traffic safety, suitable protective measures must be taken. This is especially important for heavily used traffic routes in the mountains. Mountain forests offer natural protection against avalanches. However, these are not always sufficiently available, so that other measures are required. These measures include different types of shoring, each with specific tasks. There are shoring systems that are designed for permanent or temporary use. Temporary structures do not need to be used for longer than a maximum of 50 years because they only serve to bridge the gap until, for example, a mountain forest in the corresponding area can perform its natural protective function.

Snow rakes should prevent the onset of avalanches

Snow rakes are one of the methods of avalanche protection. They can be made entirely of wood, steel or a combination of both materials. In general, steel structures belong to the group of permanent structures, and wooden structures to the group of temporary structures. The purpose of snow rakes is to prevent the snow cover from being torn away, thus counteracting the formation of avalanches. Temporary snow rakes must remain stable enough for the mountain forest to provide sufficient protection. For this purpose, certain things, such as the type of anchoring in the ground, must already be taken into account when constructing the snow rakes. But maintenance also plays an essential role. Particularly with wood, in an exposed location such as in the mountains, not only snow but also rain, solar radiation, wind and extreme temperature fluctuations as well as insects and fungi can cause damage. For this reason, those responsible are nowadays increasingly relying on snow rakes made from a wood-steel combination.

Despite difficult environmental conditions, wooden snow rakes are suitable

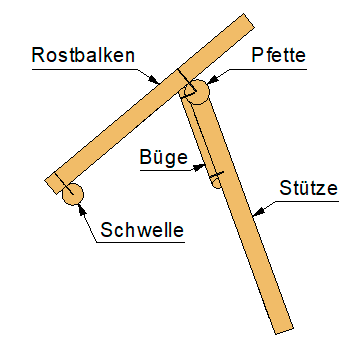

Wooden snow rakes essentially consist of several grate beams, which are connected in the direction of the ground by a sill and towards the top by a purlin. The purlin also rests on two supports. Depending on the slope, the snow rakes must be aligned at a certain angle. The grate beams are in fact those elements of the snow rake which, as a surface, absorb and distribute the pressure of the snow. Depending on the type of anchoring, the sill and supports are in contact with the ground. If this is the case, the snow rake is more susceptible to wood damage. However, if this and other wood protection measures are taken into account, according to Benjamin Müller’s master’s thesis, wooden snow rakes are quite suitable as avalanche protection measures for a period of 30 to 40 years. This observation is initially based on geometric measurements and visual inspections for externally visible damage such as broken structural elements, cracks or fungal infestation of the wood. Although various damages could be documented, the overall result shows that the assessed wooden snow rakes are still able to withstand the typical snow amounts in the Grüneck area even after 25 years.

Drilling resistance measurement with IML-RESI PowerDrill® confirms sufficiently long stability of the wood cutting rakes

Visual inspections, have their limitations in assessing the actual condition of wood. A timber may appear intact on the outside, while rot or similar damage has already spread inside the wood. A drilling resistance measurement using IML-RESI PowerDrill®, on the other hand, can reveal the full extent of wood damage at an early stage and show the condition inside the wood. For this reason, the analysis of the drilling resistance measurements as part of the master’s thesis provided important information for a realistic and reliable assessment of the stability of the wood cutting rakes. The drilling resistance measurements largely confirmed the findings from the geometric surveys and visual inspection. The more extensive recording of the wood condition by the drilling resistance measurement thus increases the validity of the assumption that wooden snow shears are basically suitable as avalanche protection for a period of 30 to 40 years.

Measurement No. 268 – Example Intact (mold only on surface)

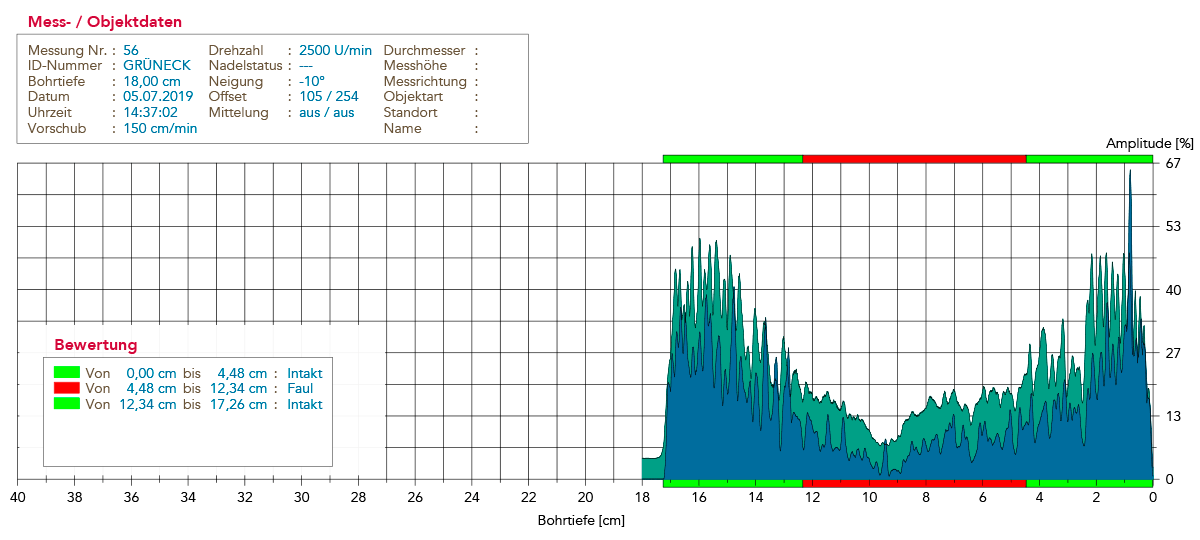

Measurement No. 56 – Example with internal rotting

Measurement No. 104 – Example with external rotting

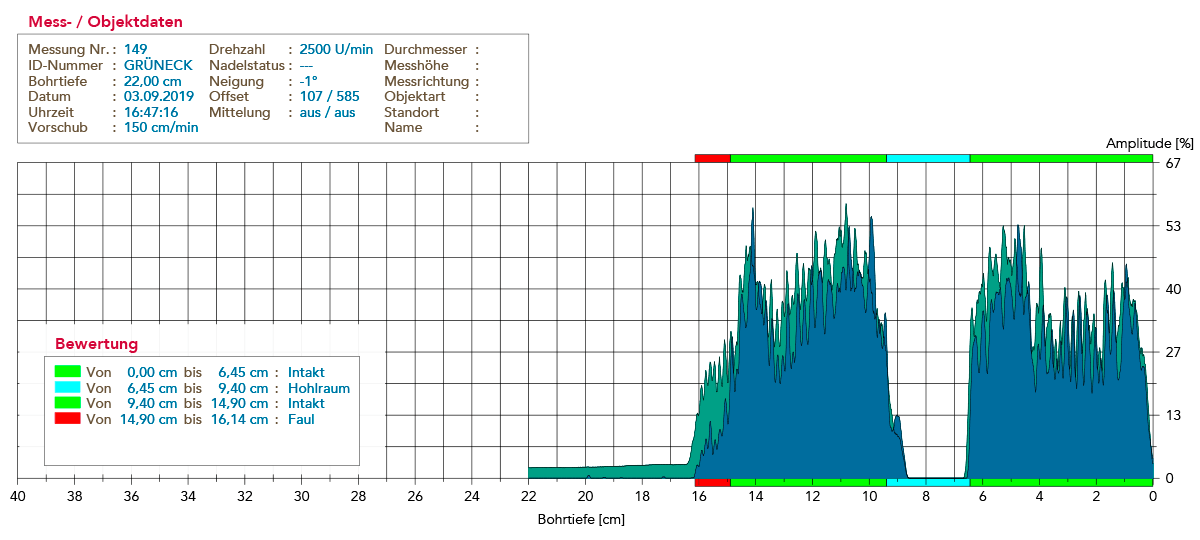

Measurement No. 149 – Example with crack

Measurement No. 175 – Example with hollow rot

For snow rakes wood as a building material has economic and environmental advantages

The Master’s thesis findings on the stability of wooden snow rakes suggest that more snow rakes made entirely of wood could be used again in the future. This is because, if the wooden construction is sufficiently durable, it has a number of advantages

over constructions made of steel or combined constructions of steel and wood. At the end of the required service life, wooden structures can simply remain on the slope until they decay naturally. Structures with steel, on the other hand, must be dismantled when they are no longer needed. This increases the costs, so that the construction made of wood is consequently also economically advantageous. For the calculations on economic efficiency, the Traunstein State Building Authority, among others, provided data. Since wood is a renewable raw material, wooden constructions are also considered to be more ecological than those made of steel.

Summary Benjamin Müller

Safety-relevant structures must be inspected within regular intervals. In impassable terrain, this in itself is a demanding task. In addition, in the case of wooden structures, the external appearance does not always match the actual condition, which makes it difficult for the inspector to make the correct assessment. The structural inspections at Grüneck have made it clear how important it is to use additional tools, such as drilling resistance measurement. On the one hand, this reduces the risk of overlooking damage, and on the other hand, the potential that still exists can be better exploited. Thus, on the one hand, the functional efficiency of the structures is ensured and, on the other hand, their useful life and economic efficiency are increased. I am therefore grateful for the trust that IML Instrumenta Mechanik Labor System GmbH has put in me by providing the IML-RESI PowerDrill® to carry out the structural tests. Without this support, the investigation would have been significantly reduced in its informative value and thus much less representative. Within the study, more than 450 drilling resistance measurements were carried out with the IML-RESI PowerDrill®. During the project, the measuring instrument proved to be very user-friendly, low-maintenance and reliable. Another benefit is the direct display of the result during the execution of the measurement. The observation of the results during the measurement coupled with the acoustic drilling noise helps in the immediate assessment of the wood substance. The evaluation of the acquired data was also easy and effective due to the PD-Tools Pro software provided. In addition to an excellent measuring device, the good service and support for all questions is outstanding.